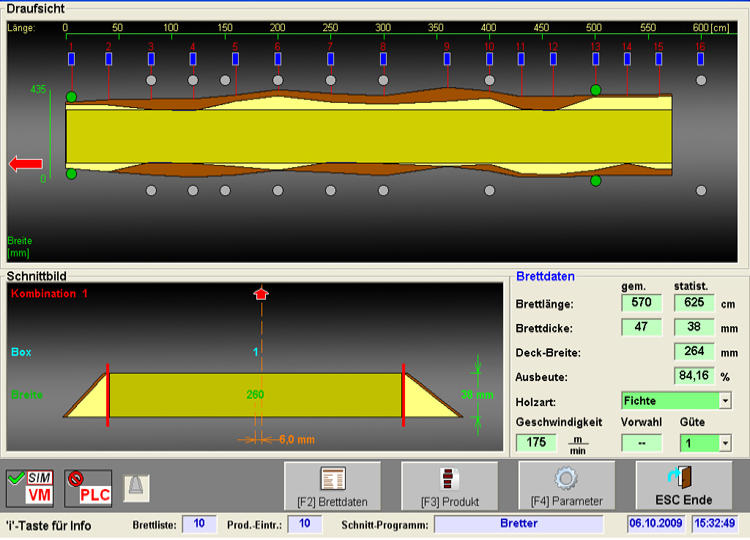

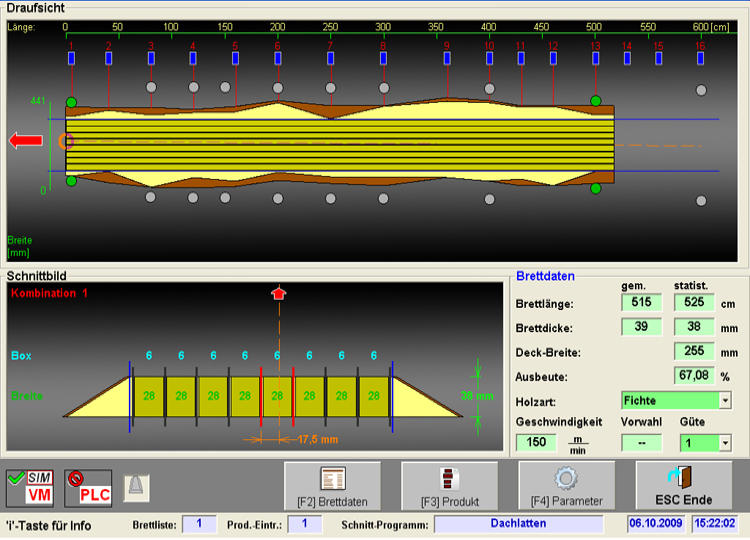

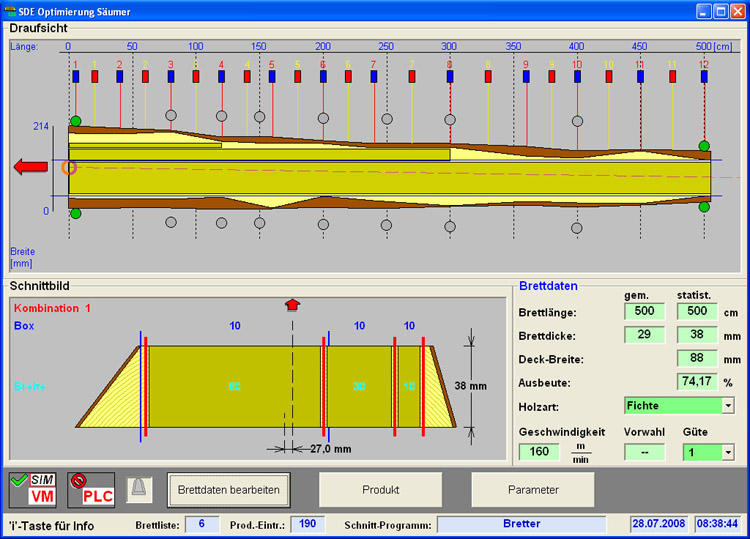

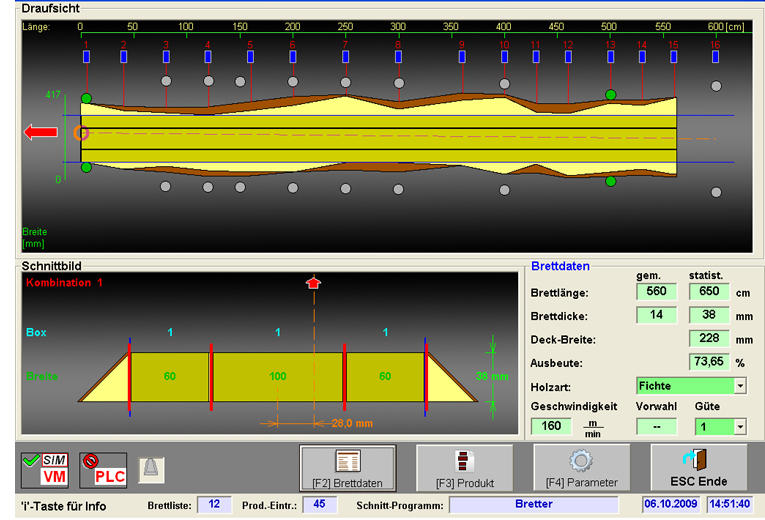

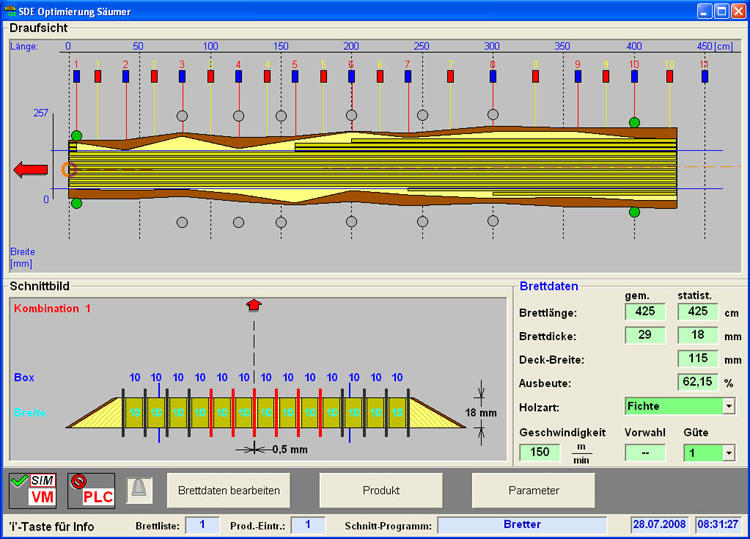

The software shows the timber in top view as well in side view. You can see all important components e.g.

potition of boards, outer shape, position of saws etc.

The system can control up to 6 variable axes and in addition to that up to 2 x 8 fixed saws (compare pattern)

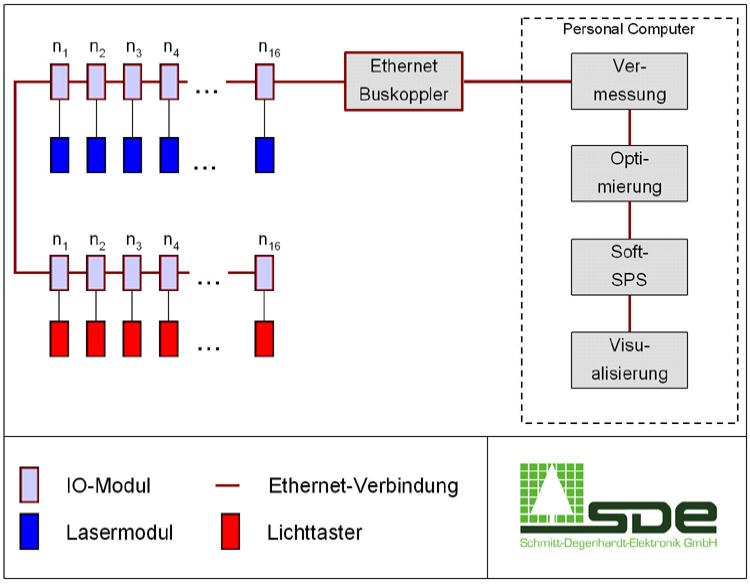

The software can operate up to 48 upper laser and 48 lower laser. There are used to measure the conture of the board.

Additionally there is the option to operate with up to 48 light sensors for more precision inf length detection.

The location of the lasers and light sensors can be defined flexibily.

1. One board :

4. Fixed saws :

The image show you a board with 2 variable saws and some fixed saws.

Alternatively you can optimize the width of top surface, to maximize the utilization of the surface.

5. Shorted slats a :

Automatic detection of sharply edged boards (settings in parameters).

Visualisation of all sensors in order to analyse hardware problems quickly and easily.

Easy selection and deselection of all sensors.

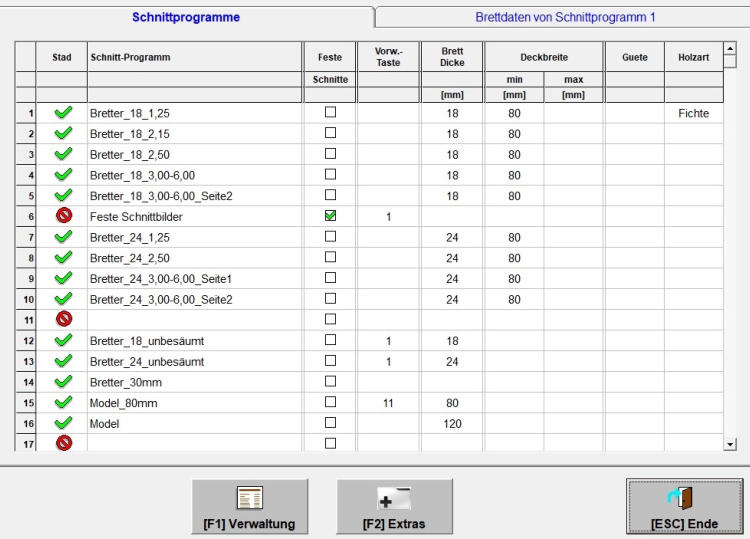

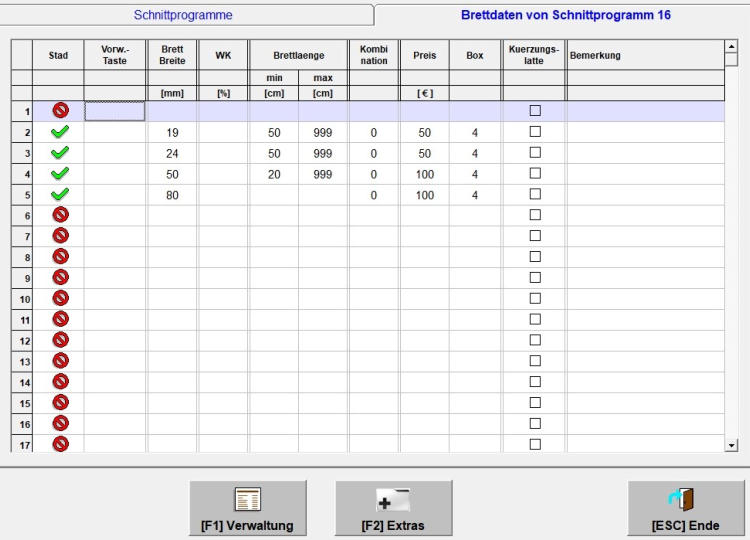

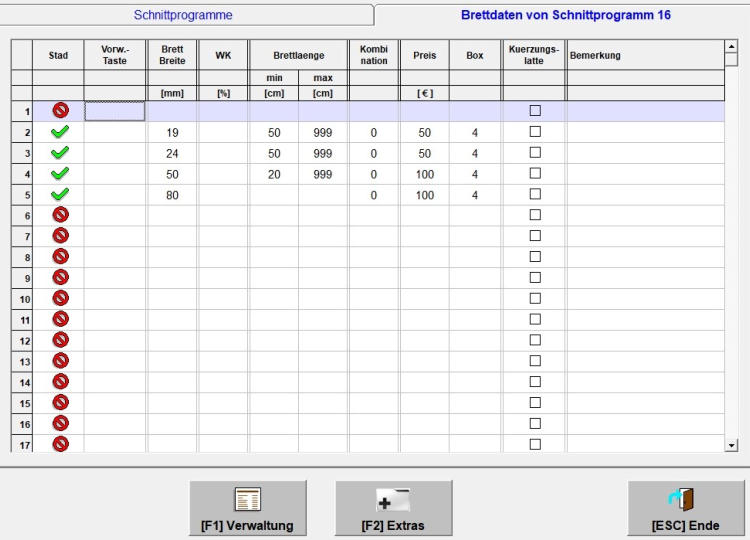

7. Cut program :

In the cutting program you can define what kind of assortment will be sawn (selected by thickness for example)

Up to 50 cutting programs can be generated.

8. Board program :

The Submenu give you the opportunity to define board parameters precisely.

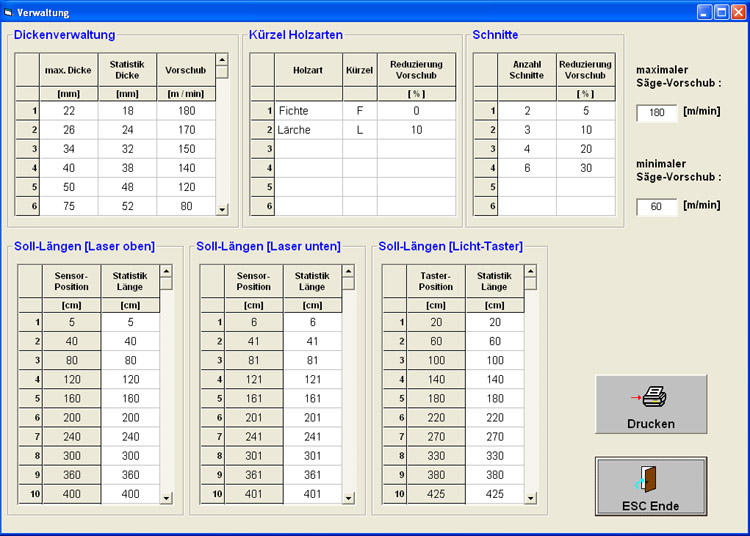

10. Administration :

In the Administration-menu the thickness of the boards can be specified with tolerances.

The feed can be reduced in the timber to board thickness, wood type and number saws.

12. Block diagram :

The communication between the hardware and software components are working via an Ethernet connection.

The image shows a plank timber with 4 variable saws.

2. 3-boards :

Here you can see a plank timer with 5 variable saws.

3. 4-boards :

By the alignment you can also choice a fiber parallel cut.

The plank timber can be shorted, to get the maximum utilization of the board.

6. Shorted slats b :

Here shorted slats are shown in combination with 6-variable saw axes and some fixed saws.

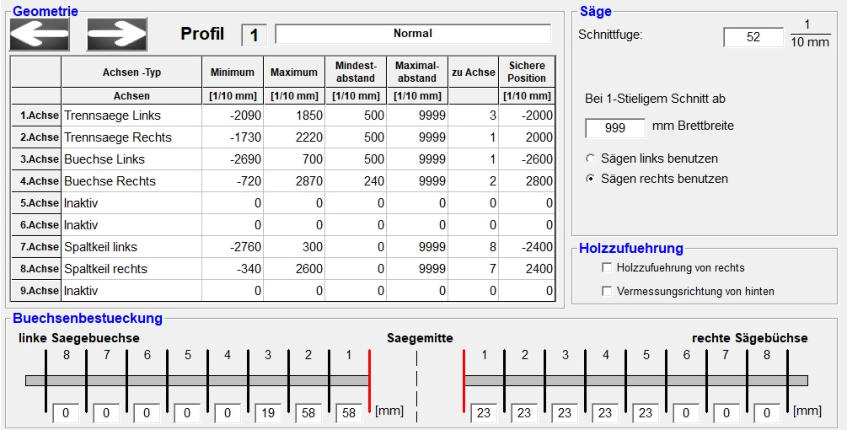

11. Profile for Machine setup :

Up to 6 profiles can be stored for machine setup.

This means, that the data does not always have to be entered again after a modification of the saws.

9. Fixed cuts :

Here, fixed stem widths can be stored which are selected depending on the preselection key, deck width and board length.

The alignment can be aligned by cover surface, or centered.

Trimming the maximum deck width can also be selected here.