SDE offers modular software components around the

different processing steps of a modern sawmill.

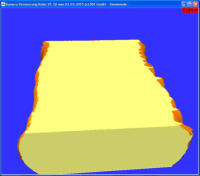

With the camera surveying the 3D contour of a log, a model, or a board will be

measured in continuous flow path .

For the capturing of the entire form there are usually multiple camera views required,

which are assembled calculational.

The analyzed data will be transfered to an optimisation.

This program analyses the log data. The bend (if necessary) and taper is evaluated.

Now the operator has the opportunity to choose between several cutting proposals

that are calculated by the program.

Raw logs are transported on the conveyer to the correct position under the

drop saw and afterwards cut automatically.

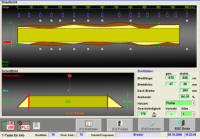

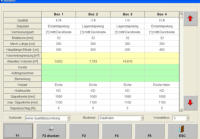

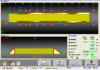

The upper image shows you the calculation module of the length optimisation,

the image below the corresponding visualisation module.

In the first step the log sorting system detects the volume of every log by using

a 2D respectively 3D measuring system. Than the transport and throw in into the

boxes that were defined before is coordinated.

In correspondence with the SDE Length optimisation a fully automised process

of the entire log sorting device is possible.

The SDE Sawing pattern optimisation is aligned to modern, quickly adjustable

Saw blades and Chipper canters.

Based of the volume of every single log and under consideration of the purchase

orders the program generates a sawing pattern.

The system calculates side products under consideration of running costs.

The side products a optimised according to profit maximum rather that to yield.

Also the calculation of the chipper canter jump and board capping are

considered in the optimisation process.

Here you can find further examples of sawing pattern:

Order list

Sharp cut

Core plank

Quarter timber

Nonstandard

pattern

Two boards

SLS Model

BBS Model

Basically this software module arranges the process and control of the entire saw line.

The operator can follow the process steps on the screen.

Both options are possible: One saw station in the line as well as two or

more saw station in the line.

These are the process steps controlled by this module:

Positioning of Chipper canter axe and saw axes

Log tracing within the entire line

Reporting of all sensors

Control of drives and hydraulic components

(e. g. prick roller, pressure roller, chain bed conveyor a. s. o.)

Our software for controlling a bandsaw works under

Consideration of:

up to 6 individually movable clamping blocks

implementation of a Chipper canter

including a chop saw is possible

short cycletimes

diagonal alignment of the log

high flexibility regarding product range

automatic infeed under consideration of

blade fluctuation

input current of band saw

fully automated process

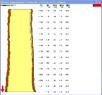

The SDE Säumersteuerung can control up to 6 variable sawing axes.

The Laser measures the board in cross direction.

There are up to 48 laser over and 48 laser below the Board.

For better length detection, light sensors can be attached.

The status of the laser or light sensors are shown in the visualization.

1. One board

2. 3-boards

3. 4-boards

4. Fixed saws

5. Shorted slats a

6. Shorted slats

b

7. Cut program

Profil-Scanner

Single-Profil

interpolation

point

Topview 1

Topview 2

measuring

points

Volume model

Camera surveying

Length optimisation

Log sorting

Sawing pattern optimisation

Automatic sawline

Log bandsaw

Edger control software

Here are some pictures of the user interface:

Board sorting

Level sorting

The principle of the level sorting is equal to those of the box sorting.

In this case to boxes for the boards are arranged horizontally.

That means that you have fewer boxes but more storage per box.

The sawing pattern optimisation program can be adjusted to defined sorting and

random sorting. One can distinguish between box sorting and level sorting.

Box sorting

Initially the shape of every board is detected.

In terms of a random sorting the software takes over the decision for a box

independently based on the current sorting list.

Thus the sorting process becomes very flexible and it works always according

to the most urgent purchase order.

In accordance with the requirements of the saw mill operator the board sorting

system can be implemented as a defined sorting.

In this case the box numbers will be defined manually.

This software calculates the pick and place position of a portalrobot.

The board is stacked with vacuum sauger.

The contour of the boards is detected by laser measurement. The software will

calculate the optimum position and rotation of the boards for each layer.

The great advantage of this stacking method is the packing density.

The boards are then stacked into each other, so that only a few

stabilising planks must be placed.

The data will be corrected when a board is cutted by the length..

From the measured data, the sales widths and Lengths are determined.

These can be detained in a file for further processing.

The software supports automatically to sign the boards,

the processing of wood moisture and the package weight.

For quality assurance, each board can automatically photographed and

be traced by means of image file to each stack.

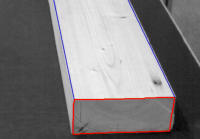

The product DrawCut shows the dimensions in a live image of a Camera.

So it is possible for example to find positions for a log bandsaw.

The on-screen dimensions are corresponding with the real coordinates

of the machine.

We have some proven software modules, which are usually adapted to the corresponding plant.

9. Fixed cuts

8. Board program

11. Profile for

machine setup

Visualisation

Mainmenue

Sample 1

Sample 2

Sample 3

Order

Distribution

Optimisation

Cut pattern

10. Administration

Manuel

editing

12. Block diagram

Stacking area storage

The program consists of 2 components

1. Storage and management

2. Outsourcing (is installed in the existing project at 4-stations).

The input stacks the specified lumber from a task package

into the storage bins created for it.

The software transfers to the portal robot the pickup positions, travel distances

and set-down positions for the lumber and any intermediate bars for stabilization.

(On the left a picture of the stock overview)

During storage, the lumber is placed in the appropriate storage bin.

The quantities, maximum stack heights, etc. are managed here.

Several wood designations (KVH,BSH...) can be stored.

so that the lists remain clear and are quickly accessible.

(On the left a picture of the input storage)

When stacking, different timbers can be taken from a pallet.

If woods have already been taken, you can deactivate them.

(On the Left a picture of the stack)

When removing from storage, first select the corresponding list of dimension (the

dimensions are sorted in ascending order).

After that, you specify the required number of pieces and confirm the input.

The lumber is then picked up fully automatically from the corresponding stack and

where placed at a predefined position.

At the moment there are 4 outsourcing places available.

(On the left a picture of the output stack)

In this type of storage, the timber (bars, beams, squared lumber and boards) are

simply stacked on the floor of the hall with a portal roboter.

There is no other device for aligning the wood. Therefore, the storage of different dimensions is relatively simple.